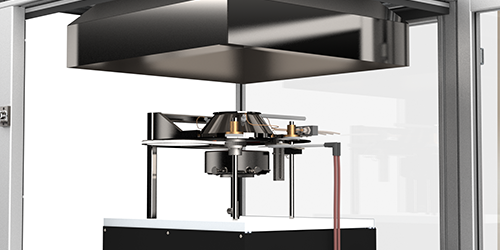

Cone Calorimeter ISO 5660-1

Characteristics

- Reaction-to-fire tests - Heat release, smoke production and mass loss rate

The test device is used to access the reaction of building materials to the effect of heat.

Heat release, smoke production and mass loss rate are measured.

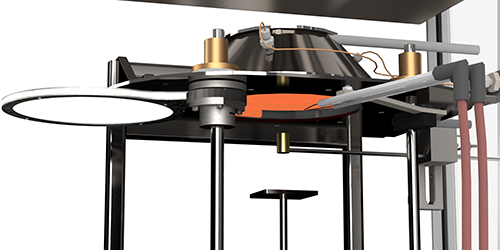

The main function of the Cone Calorimeter is based on the knowledge that the net heat of combustion is in fact proportional to the amount of oxygen required for combustion. The ratio is approximately that 13.1 x 1000 kJ of heat is released per kilogram of oxygen consumed during combustion. The samples are irradiated under laboratory conditions, ignited by sparks and thereby burned. They are exposed to thermal radiation at fixed intervals between 10 kW/sqm - 75 kW/sqm and the changes in oxygen and gas concentration are measured. The principle is called the "oxygen consumption principle" and originates from calorimetry.

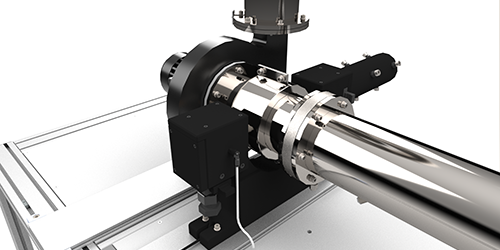

Furthermore, the flow rate in the exhaust pipe and the loss of mass of the sample are measured. Smoke obscuration is measured as the intensity of the laser light that is transmitted through the smoke in the exhaust pipe. The measurement is used to calculate the extinction coefficient according to Bourger's law. The test results are used to determine smoke production and smoke production rate.

Additional modules

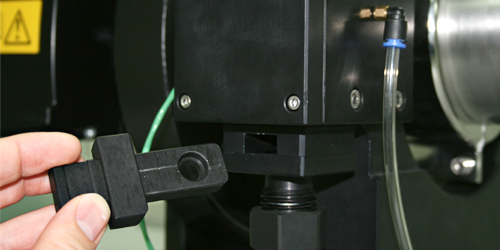

FTIR-spectrometer

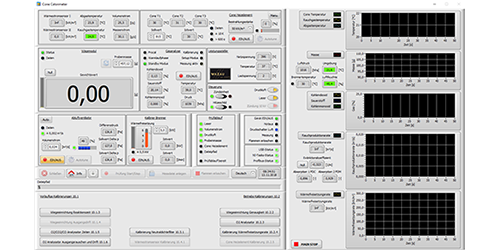

Technical specifications

| Type of specimen: | Textiles, plastics, floor coverings, building products, solid materials of all kinds |

| Test standards: | ISO/DIS 5660-1 |

| Sensors: | Temperature heater, time, gas analysis O2, CO and CO2, optical light measuring section, differential pressure measurement exhaust pipe, electronic precision scale, ambient temperature, air pressure, humidity, heat flow sensor type Schmidt-Boelter, exhaust gas temperature, temperature light measuring section, flame protection calibration burner |

| Special features: | Instrument control, measurement data recording and evaluation via integrated PC, fully integrated design with enclosure of the test table, largely automated test and calibration runs, pneumatic movement of heat protection shield and ignition spark generator, electronic brand precision scale, sample gas processing without addition of chemicals, cooling of heat flow sensors without water connection. |

Supplies: | 3 ~ 400 VAC / 6 kVA Flue gas extraction, compressed air Methane gas, nitrogen, calibration gas |

Dimensions: | approx. 2000 x 3000 x 800 mm (W x h x d) |

Weight: | approx.. 400 kg |