Characteristics

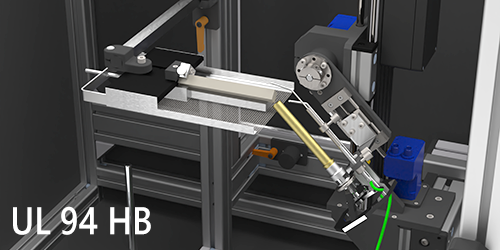

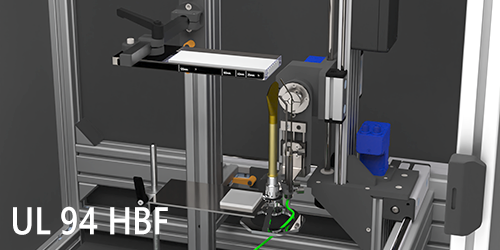

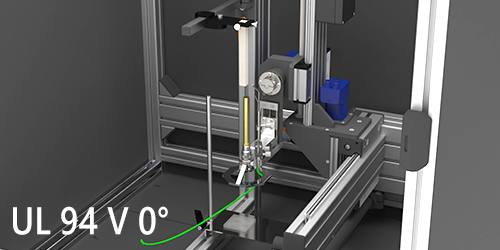

- Tests determining the fire hazard.

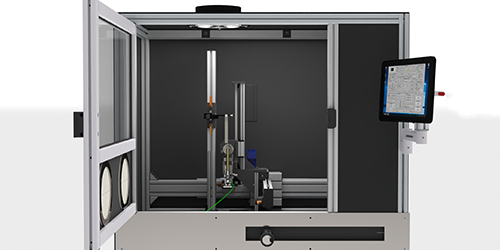

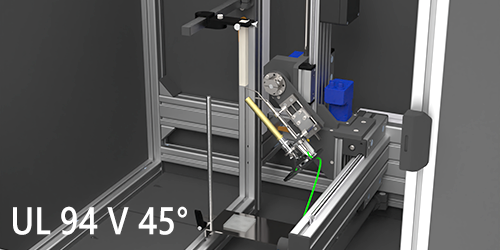

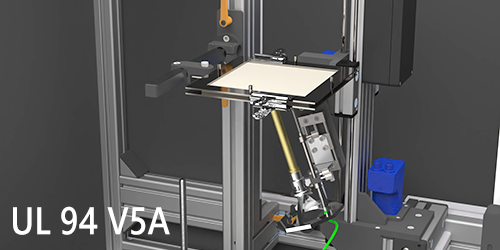

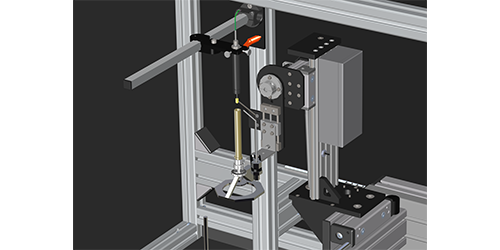

The test device is equipped with a 4-axis burner position control. Two of the axes are moved electrically (burner height, burner angle) and controlled by the integrated mini PC. The operation is done via a touch screen display.

The gas control is also electronic, controlled by the device software. The device software supports you during the tests by specifying the exposure times, setting time events, moving the burner vertically into the test position and tilting it if necessary.

If it is necessary to track the flame during a test, the software remembers the procedure of the first test and can then follow this procedure during subsequent tests.

Furthermore, a largely automatic calibration device is provided for adjusting the flame output. Depending on the standard, tests can be performed with the 50 W test flame or the 500 W test flame.

For safety reasons, the burner is equipped with an electronic pilot flame safety device, which is implemented with a thermocouple.

Additional modules

- Electrical ventilation flap

- Additional specimen holders

- Drawer insert

Technical specifications

| Type of specimen: | Plastic materials |

| Test standards: | UL94 EN 60695-11-10, EN 60695-11-20 ISO 9772, ISO 9773 ASTM D 635, ASTM D 3801, ASTM D 4804, ASTM D 4986, ASTM D 5048 |

| Special features: | Integrated Mini-PC with touchscreen for device control and Measurement data logging. Semi-automatic calibration device for flame output adjustment. Semi-automatic test procedure. Multiaxial electronic burner position control. Depending on the standard, tests can be performed with the 50 W test flame or a 500 W test flame. The test equipment is provided with a flame protection device. |

| Sensors: | Temperature Time Gas pressure Gas flow Ambient temperature Humidity |

| Supplies: | 230 VAC / 400 VA Methane gas |

| Dimensions | 1170 x 800 x 1880 mm (W x h x d) |

| Weight (test device): | approx. 150 kg |