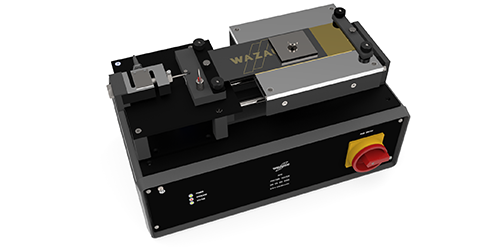

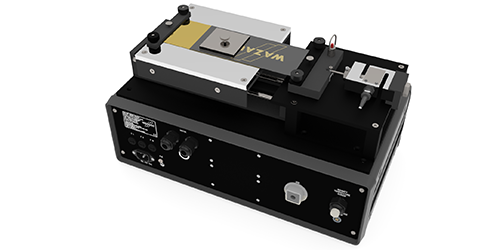

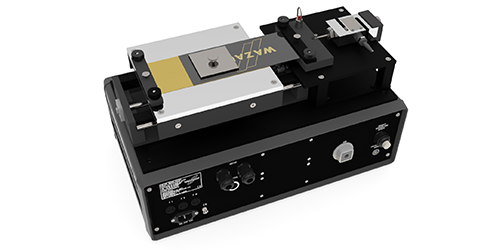

Friction testing device RPG DIN EN ISO 8295

Characteristics

- Determination of the friction coefficients of plastics, films and sheets.

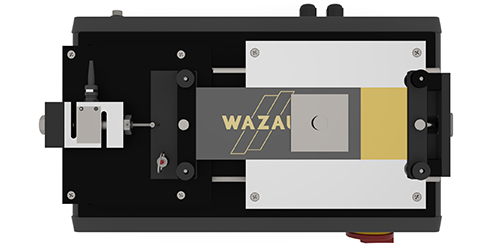

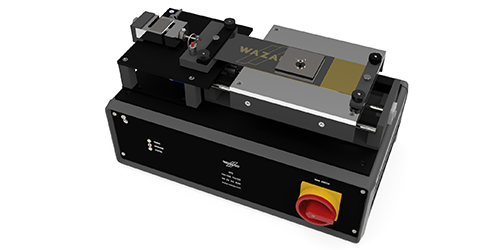

The device is used to test the friction behavior of two partners that are moved relatively to each other. The test can be performed in accordance with DIN EN ISO 8295 (Plastics - Films and webs - Determination of coefficients of friction) and is primarily used for quality control. For the test, the lower specimen - in case of testing against metal, a corresponding metal surface - is fixed on the measuring slide. The holding device, which is connected to a force measuring device via a spring, holds the second, upper specimen. A surface pressure is generated in the friction couple via a weight specified by the corresponding test standard.)

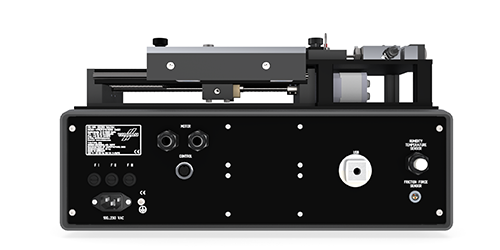

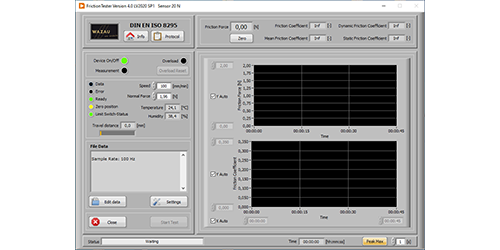

During the measurement, the measuring slide is moved at a defined feed rate (100 mm / min) against the resistance of the friction pairing, and the magnitude of the generated frictional force is registered via the force measuring device. The measuring path is approx. 60 mm. The feed rate can be set between 5 - 300 mm / min in the software before the measurement.

The device can be configured in each case so that both the static and dynamic coefficient of friction can be determined.

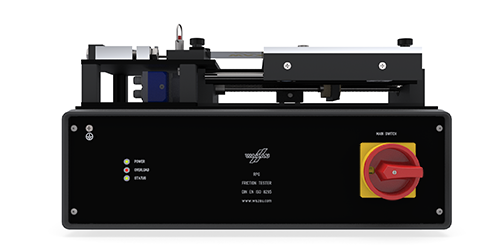

The friction tester is equipped with a friction force sensor of 20 N, which is connected to a computer via a measuring amplifier and a USB interface. The software works in conjunction with a USB- measurement module, which has a resolution of 14-bit. The measuring slide can optionally be equipped with a heating plate, which is fixed from below. The temperature of the measuring slide can now be heated up to max. 80°C.)

Technical specifications

| Type of specimen: | Plastic film and sheeting |

| Testing standards: | DIN EN ISO 8295 |

| Sensory functions: | Friction force sensor 20 N |

| Power input: | 100 - 230 VAC / 150 VA |

| Dimensions (testing device): | 475 x 321 x 250 mm (W x D x H) |

| Weight (testing device): | approx. 20 kg |

| Opotional | Notebook with pre-installed device software |