Tribometer SVT 500-1000

Characteristics

- Tribological testing in translational movements

The tribometer is used for examining and simulating friction and abrasion processes under translational load. It can be operated without lubrication with solid objects and with fluid lubricants with boundary or mixed friction. Thus both materials and lubricants can be examined.

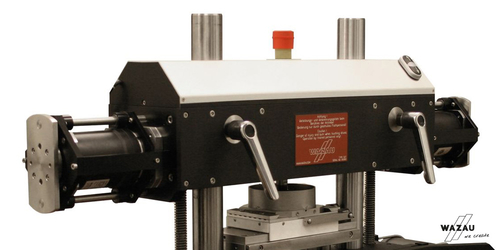

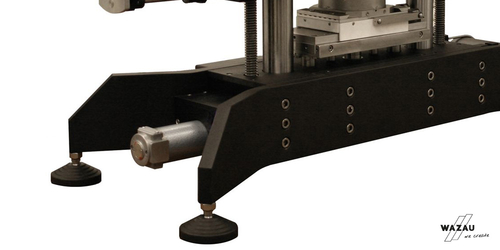

In the standard testing procedure a stationary specimen (pin or ball) is pressed against the front surface of a disc with a defined normal force. Both specimen are arranged vertically, the fixed disc being positioned below. The normal force is applied by a motor spindle system. The device is driven by two continuously variable (0.1 – 20 mm / 0 – 40 Hz) linear synchronous motors. The actual testing device consists of the motor unit, the drive unit and the load component. The assemblies are fixed n top of each other in a slideable manner to two vertically positioned bars. During the testing a continuous measuring of the normal force, the ambient temperature in the bowl, the linear distance of both friction materials, the rise and the reactive friction force takes place. The specimen bowl can be heated between RT and 150°C. A K-type thermocouple in the specimen bowl provides temperature measuring and adjusting. The reactive friction force is measured by a force sensor. All measurement signals are sent to the control cabinet and processed accordingly. The data collection is provided by a multi-functional data collection module with a resolution of 16 Bit and the software provides a measuring frequency of 0.01 - 100 Hz. The software is used for controlling and measurement data recording purposes.

Technical specifications

Type of motion: | Swinging |

| Kind of motion: | Continuous - translatoric linear oscillation |

| Geometry of specimen: | Pin - disc / ball - disc |

| Lubricant: | Without / fluids |

| Actuating elements: | Normal force / elevation / frequency / temperature |

| Sensory functions: | Normal force / reactive torque / distance / temperature / elevation |

| Normal force: | 5 - 500 N / 5 -1000 N (dynamic transfer of force) |

| Elevation / frequency: | 0,1 – 20 mm / 0 - 40 Hz (depending on model) |

| Temperature: | RT - 150° C |

| Reactive friction force: | 100 / 200 / 500 N torque shaft (depending on model) |

| Drive unit: | Air bearing |

| Power input: | 3 ~ 400 VAC / 10 kVA (depending on model) Compressed air |

| Dimensions (testing device): | ca. 950 x 450 x 550 mm (W x D x H) |

| Weight (testing device): | ca. 100 kg |