MMS - ISO 9185 | ASTM F955

Characteristics

- Evaluation of material resistance to liquid metal splashes on protective clothing.

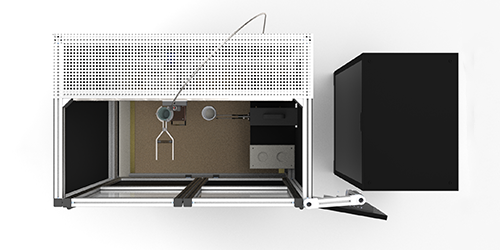

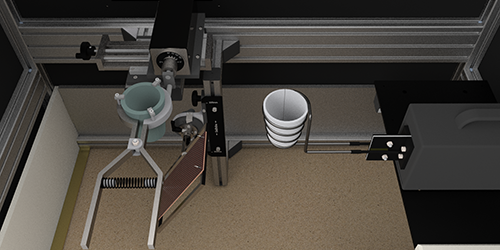

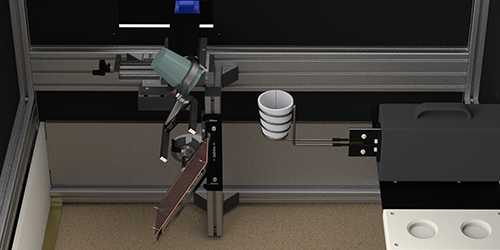

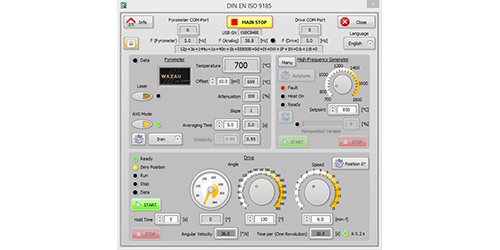

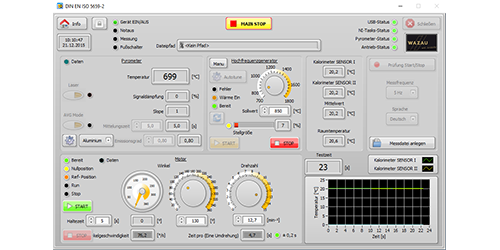

When testing materials according to DIN EN ISO 9185, defined quantities of molten metal are poured onto the specimen, which is held at an angle to the horizontal on a mounting frame. The damage is evaluated by placing a PVC film immediately behind and in contact with the specimen and assessing the changes in the PVC film after casting.

When testing materials according to ASTM F955, defined quantities of molten metal are poured onto the specimen, which is held at an angle to the horizontal on a sensor board. Damage is assessed by having 2 calorimeters measure the temperature rise immediately behind the specimen.

Additional modules

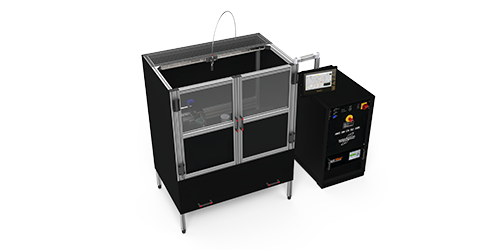

The device is available as EN ISO 9185, ASTM F955 or as a combined device.

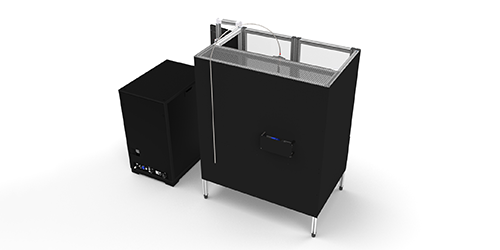

Industrial cooler 1700W for induction furnace. This eliminates the need for water and waste water connections.

Technical specifications

Type of specimen: | Materials for the fabrication of protective clothing against large amounts of molten metal. |

Testing standards: | ISO 9185 ASTM F955 |

Sensors: | Melt temperature 2 calorometers (ASTM F955) |

| Special features: | Induction furnace with high frequency generator Device enclosure Hinged safety switches in the doors allow testing only when the device is closed Pyrometer can be moved on linear guide PC with touch screen monitor integrated into the control cabinet |

Supplies: | Three-phase current, 3 ~ 400 VAC / approx. 6 kVA Water |

Dimensions: | Test stand: approx. 1270 x 1550 x 875 mm (W x H x D) Control cabinetk: 550 x 1000 x 800 (W x H x D)

|

Weight (test stand): | approx. 260 kg |

| To be provided by the customer: | Wastewater connection, sink sufficient Exhaust air extraction |